Power-to-X: A key tool to decarbonise our society

Climate change is one of the biggest challenges of our time. With the Earth’s temperature rising at an unprecedented rate, it is imperative that we transition to clean and sustainable energy sources. Electrification is our main strategy to help us replace fossil fuels, but there are some applications that are difficult to electrify. This is where Power-to-X comes in, particularly the role of hydrogen. Power-to-X refers to the process of converting electricity from renewable sources into fuels and chemicals. This field is key to achieve our climatic goals because it allows us to decarbonize applications that are difficult to electrify, especially industrial processes such as steel and fertilizer production or heavy-duty transportation, aviation, and shipping. Therefore, hydrogen plays a key role in this field, as it is a versatile energy carrier that can be used for a wide range of applications essential to produce all these fuels and chemicals.

Currently 70 million tonnes of hydrogen are used per year, with the majority being used in the refining and chemical industries (i.e., fertilizer production). However, as we transition to a low-carbon economy, we will need significantly more hydrogen. The European Union (EU), United States, and China have all announced plans to scale up hydrogen production, with the goal of exceeding 100 million tonnes per year by 2050. Closer in time (i.e., 2030) plans are quite different in terms of ambition. For instance, the EU aims to have 20 million tonnes of renewable hydrogen per year by 2030 with the goal to produce 10 million tonnes internally and to import 10 million tonnes from outside the EU. On the other hand, both China and USA aim to produce only to 2 million tonnes of renewable hydrogen per year by 2030.

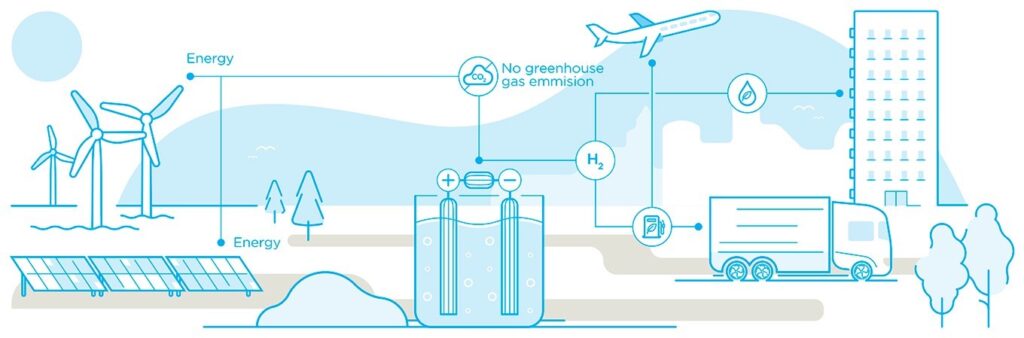

Green hydrogen is produced by using renewable energy – for example, produced from offshore wind farms – to split water into hydrogen and oxygen in an electrolyser without producing greenhouse gas emissions. The green hydrogen can either be used directly or synthesised using chemical processes into other fuels such as methane, methanol and ammonia – for use in hard-to-electrify sectors such as heavy transport and industry

There are different types of renewable hydrogen, including turquoise, blue and green. Turquoise hydrogen is produced through methane pyrolysis; blue hydrogen is produced from natural gas with carbon capture and storage; while green hydrogen is produced from the electrolysis of water and using renewable sources such as hydropower, wind and solar energy. Green hydrogen is the most sustainable option as it does not rely on fossil fuels and has no carbon emissions. Electrolysis involves splitting water into hydrogen and oxygen using an electrical current. There are four main types of electrolysis technologies: alkaline water electrolysis (AWE), proton exchange membrane (PEM), solid oxide electrolysis cells (SOEC) and Anion Exchange Membrane (AEM). Different maturity levels as well as advantages and disadvantages can be found in every technology. AWE is characterized to be the most mature technology and very cost effective. PEM is also a mature technology and very compact. SOEC is very electrically efficient, made of cheap and abundant materials but less mature compared to AWE and PEM. Finally, AEM has the same advantage of a PEM while not using any expensive catalyst metal, but with the least extent of maturity among the four technologies.

The need for electrolysis capacity is closely linked to the need for new renewable energy sources. As we scale up electrolysis, we will need to ensure that we have enough renewable energy to power it. This will require a significant increase in renewable energy capacity, particularly in wind and solar energy. It will also require new infrastructure and investment in both the grid and hydrogen transport infrastructure to ensure that we can transport renewable energy from where it is produced to where it is needed and then transport hydrogen where it is cheaply produced to where it is consumed. For instance, the internal EU production plans of 10 million tonnes of hydrogen will require the installation of between 70 and 100 GW electrolysis capacity with the requirement of having new 150 to 200 GW new renewable energy generation installed with large production costs between producing in the North or South of Europe or in Central Europe.

So where do we start with Power-to-X projects? One example is the use of green hydrogen in the steel industry. Steel production is responsible for a significant amount of carbon emissions, but the use of green hydrogen in the process could help to significantly reduce these emissions. By using green hydrogen instead of coal in the steel-making process, emissions can be reduced by up to 95%. Another example of the use of Power-to-X is in the production of green ammonia or sustainable aviation fuels (SAF).

Undoubtedly, Power-to-X is starting to gain a lot of momentum. According to the Global Hydrogen Review 2022 report from the International Energy Agency (IEA), more than 150 GW in electrolysis capacity will be online by 2030. However, this will remain short to achieve the 850 GW electrolysis capacity target that it is needed to reach IEA’s Net Zero scenario. Therefore, exciting times lie ahead for everyone working in Power-to-X, but there are also many challenges in making this molecule a great tool to continue with the decarbonization of our society.

Carlos Bernuy-Lopez – Senior Consultant and Expert in Green Hydrogen – RAMBOLL